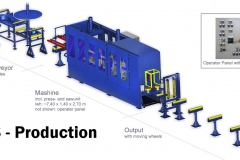

Description of the hydraulic press, type 590

- Frame

– solid, mechanically-welded steel profiles

– 6 piece floor flanges for fixing and leveling

– full, transparent protective casing of the whole machine

- Functional elements

– lower jaw HEB 300*2800, attached to the frame with a hardwood tipped concave form

– upper movable pressing jaw HEB 300*2800, the working surface of the jaws is surface-treated and equipped with a convex mold.

– the movable pressing jaw moves up and down on bronze rails.

– maximum lift of the pressing jaw is 450 mm – hydraulic lift cylinder.

– the closing limit is set according to the respective beam model, by means of a 4 nut and bolt system – via the central control and display.

– pressure cylinder return via electric probes limited to 50 mm.

– longitudinal guidance for both wood and the steel bridge adjusted with independent nut and bolts with the appliance and display.

– adjustment appliance for the contra transit.

- Drive

– input: input feed my means of an electric motor with frequency converter and rubber rollers.

– output: input feed by means of an electric motor with frequency converter and rubber rollers

– speed of the motors is controlled with the potentiometers directly on the control panel.

– two feed systems are centered automatically on the beam and work with a width from 80 mm to 120 mm and width of the upper and lower flanges of 80/160 mm.

Total thickness of the HTS hybrid beam max. 590 mm

- Guide for steel sheets and timber elements

– every individual component of the beam is directed separately between 2 rails, which can be adjusted independently.

- Cutting device

– motor with cast iron housing 4 kW 2890 RPM

– tungsten carbide saw blades, diameter 500 mm

– height adjustment by means of a hydraulic cylinder

– protective casing and sawdust collecting device

– laser cut indicator

– length measuring unit with LCD display

- Power Controller

6.1 – Hydraulic power pack

7,5 kW motor pump 451 mm pressure regulator, pressure indicator, volume throttle valve

6.2 – Cylinder

Hydraulic cylinder with 15 t pressure power

Lift 500 mm

fixed firmly on pivot

1 hydraulic cylinder with 900 mm lift to the vertical lift of the saw

- Rewinder

– 2 Flow reels on ball bearings with a sustained-action brake with adjustable reel.

- Task table

– legs fixed to the ground, height adjustable

– the lower timbers are held by rollers.

– the upper timbers are held by height-adjustable rollers.

– the steel sheet is held by 1 table and 2 adjustable rollers.

– the U rails with rollers 10 m long, with a stand and roller system is a simple and safe means of guiding the upper and lower flanges for long beams over 12 m.

– rails are fixed to the ground with anchor bolts.

- Guide rail behind the saw

– welded construction – 12 spacers 1.00 m

– adjustable height

– guider rails for runways, fixed to the ground with anchor bolts

10.Saw

– laser indication

– length measurement with a small display on the control panel

All other controls are integrated into the control panel.

Input Unit

– input of the upper and lower flange width and thickness

– input of the guide for steel sheet in various heights

– feeding and discharge rollers

– camber

– sawing and beam stabilization clamps with rollers and guide

– setting the camber

– removing waste material on a conveyer belt

– overall capacity – current 34 A – 30 kW